Supporting bearing Construction Construction and Type of Seal

2024-11-09

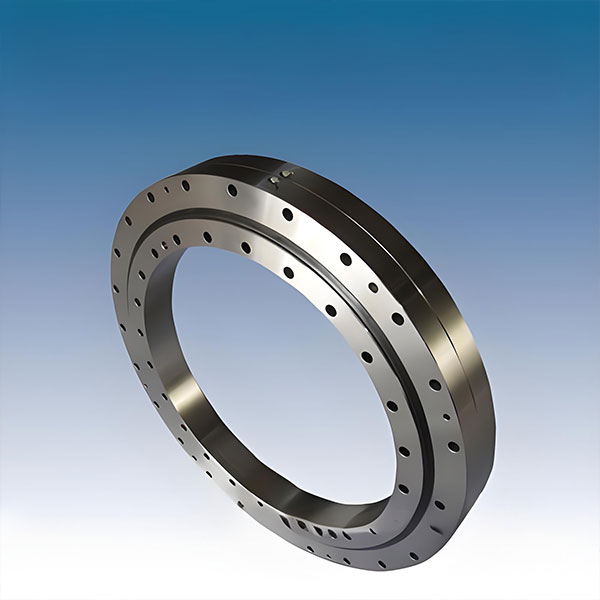

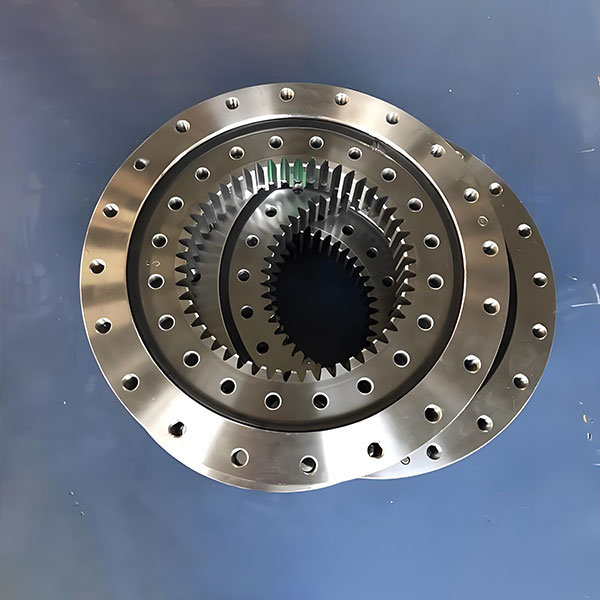

The supporting rings of the ring mainly consists of the upper ring, the lower ring and a completely compensated ball. The entire structure of the rotary ring is used to rotate at low speed and at a low load. Both single -row and two -row versions are available, as well as the convenience of pre -drilled installation holes.

In real life, the rotary bearing can control the weight difference in cold cutting up to 1%, the depth of destruction is 0.5 mm, and the end of the end surface is less than 2 ° 30. The difference in the weight of the hot cutting material can be. It is controlled within 2%, and the end line is tilted by less than 3 °. A limited cut matrix means that corruption, axial movement and flattening of the rod are limited to a radial puff. Some of these methods tighten only the end of a fixed knife, and some tighten both the end of a fixed knife and the end of a movable knife. Tighten methods include the type of cylinder and the connection of the mechanism.

The supporting bearing are typical rolling bearings with a wide range of use. They are used for high -speed or even extremely high -speed operations and are very durable. This type of bearing has low friction, high maximum speed, simple structure, low cost and allows you to easily achieve high manufacturing accuracy.

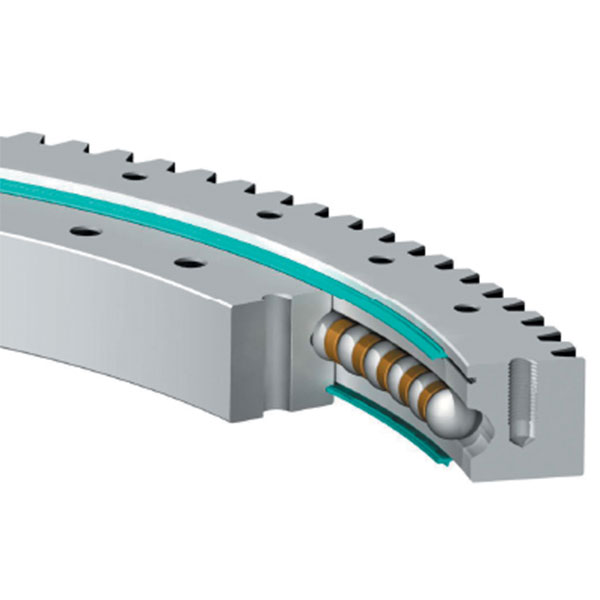

The supporting bearing also has a certain alignment ability. When it is tilted 10 degrees relative to the hole in the case, it will still work normally, but this will have a certain impact on the life of the bearing. The separators of the rotary bearings mainly are corrugated separators stamped from a steel plate, and in large bearings, whole metal separators treated with mechanical processing are most often used. The densification of the rotary bearing, on the one hand, prevents the flow of filled lubrication, and on the other hand, prevents the entry of external dust, impurities and moisture into the bearing and violation of normal operation.

Since most rotary bearings operate at high loads and low speeds, the types of bearings seals have two structures: a rubber sealing ring and labyrinth seal. The seal of the type of rubber sealing ring has a simple structure. It has become widespread thanks to a small occupied space and reliable sealing properties. However, its disadvantage is that at high temperatures, the rubber sealing edge is prone to premature aging and loss of sealing properties. Therefore, rotary bearings operate at high temperatures. Labyrinth seal should be taken.