How do turning bearings affect the ecology?

2025-03-01

content

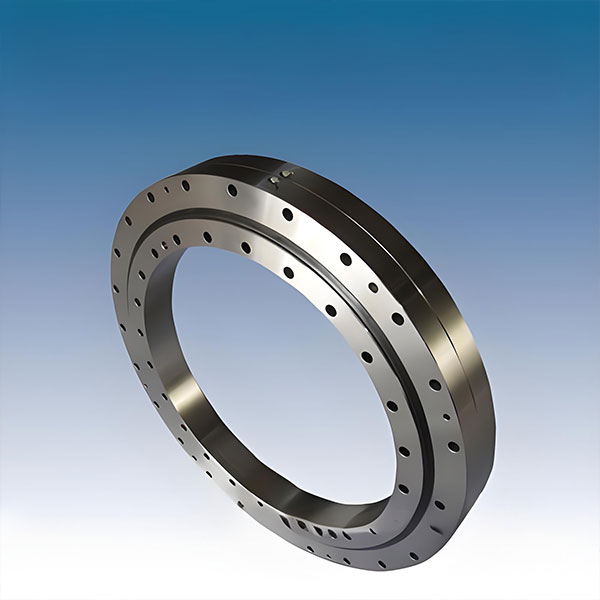

Environmental stability is becoming an increasingly relevant topic in all areas of industry, including the production of rotary bearings. The impact on the ecology of products, its production and disposal become important factors that must be taken into account.Turning bearingsThey play a significant role in various industries, from mechanical engineering to construction and energy. Therefore, it is important to understand how their use and production affects the natural environment. Effective resource management and environmental responsibility for the entire bearing life cycle can significantly reduce the negative consequences for the planet. In this article, we will consider various aspects of the environmental influence of rotary bearings, as well as ways to minimize it.

Production processes and energy

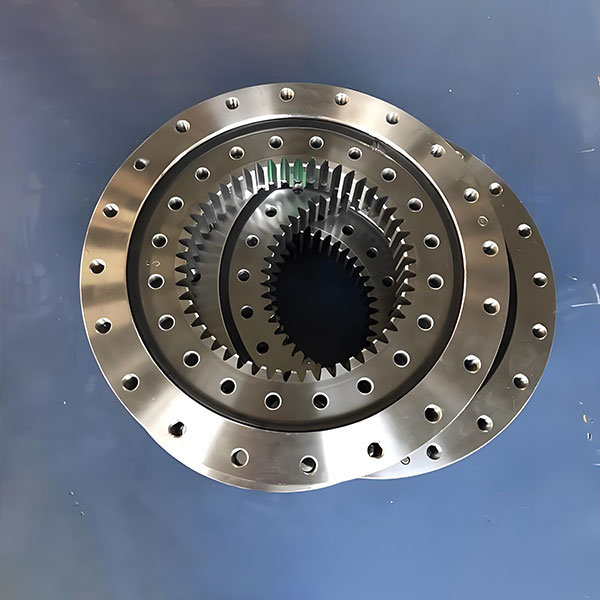

Production processes associated with the manufacture of rotary bearings require a significant amount of resources and energy. In the metalworking industry, especially in companies such as011.10 180 The bearing of a supporting rotary plant, the level of energy consumption plays a key role in the environmental impact on the environment. Modern technologies allow reducing energy consumption. The use of renewable energy sources and improving the efficiency of production processes can significantly reduce the carbon trace. In addition, increasing the accuracy and quality of manufacture reduces the amount of waste and defective products, which also has a positive effect on the ecology.

Materials and resources

The materials from whichTurning bearings, also have their own environmental impact. Steel, bronze and plastic, which are most often used in bearings, require significant efforts for production and processing. Nevertheless, there is a tendency to develop new, more environmentally friendly materials that can replace traditional ones. For example, the use of processed materials allows you to reduce the load on natural resources and reduce the amount of waste. It is important that manufacturers, such as011.10 180 The bearing of a supporting rotary plant, paid attention to environmental aspects of the supply and processing of raw materials.

Durability and reliability

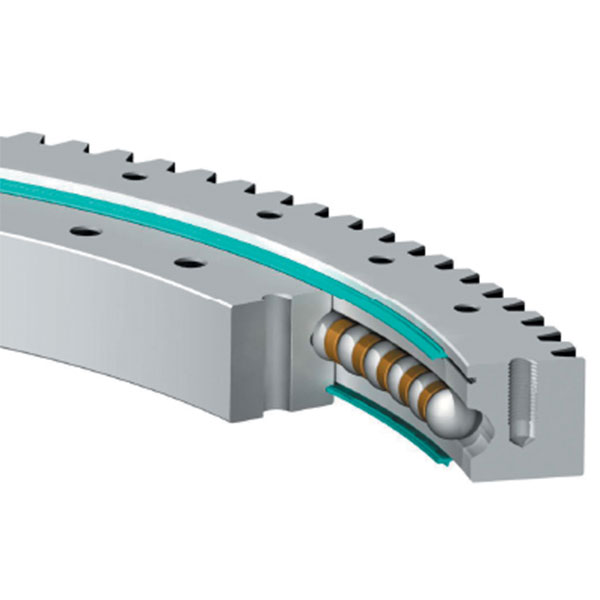

The durability and reliability of rotary bearings directly affect their influence on the environment. The longer the life of the product, the less often it requires replacement, which reduces the need for new resources and reduces waste volume. Reliable bearings reduce the cost of maintenance and reduce equipment downtime, which also positively affects the general environmental balance. Innovations in the field of production and materials allow you to create more durable and effective bearings, which serve long and reliably, reducing the need for their frequent replacement and repair.

Disposal and processing

One of the most important environmental tasks is the correct disposal of old rotary bearings. The development of processing systems and secondary use of materials can minimize the negative impact on the environment. Steel and other metals that make up the basis of bearings can be processed and used again, which reduces the load on natural resources and reduces the amount of waste. Manufacturers should strive for a closed production cycle in which the materials of the old bearings are returned to the production of new products.

Technological innovation

Technological innovations play a key role in reducing the environmental influence of the production of rotary bearings. The introduction of new methods and technologies, such as 3D printing, computer modeling and automation of production processes, can significantly improve environmental efficiency. These technologies help reduce the use of materials and energy, increase production accuracy and improve waste management. The ability to quickly adapt to new technologies will become a key factor for the sustainable development of the industry in the future.

Contribution to sustainable development

At the global level, rotary bearings can significantly contribute to the sustainable development of industry and the economy. The transition to more environmentally friendly processes and materials, improved logistics and supply chains, as well as the development of new methods of disposal and processing are part of a comprehensive strategy for sustainable development. The responsibility of manufacturers and consumers for the environmental impact of products can become a driving force for significant changes in the industry. Support for scientific research and the development of international cooperation in this area will significantly improve both environmental and economic efficiency.

Thus,Turning bearingshave great potential to minimize environmental impact. The transition to more stable production and operation methods can significantly reduce the negative impact on the planet and contribute to global sustainable development.